When I was finishing up the saw handwheel, I realized my knurling too would not knurl something as big as 2 inches, so I set out to build one that would…

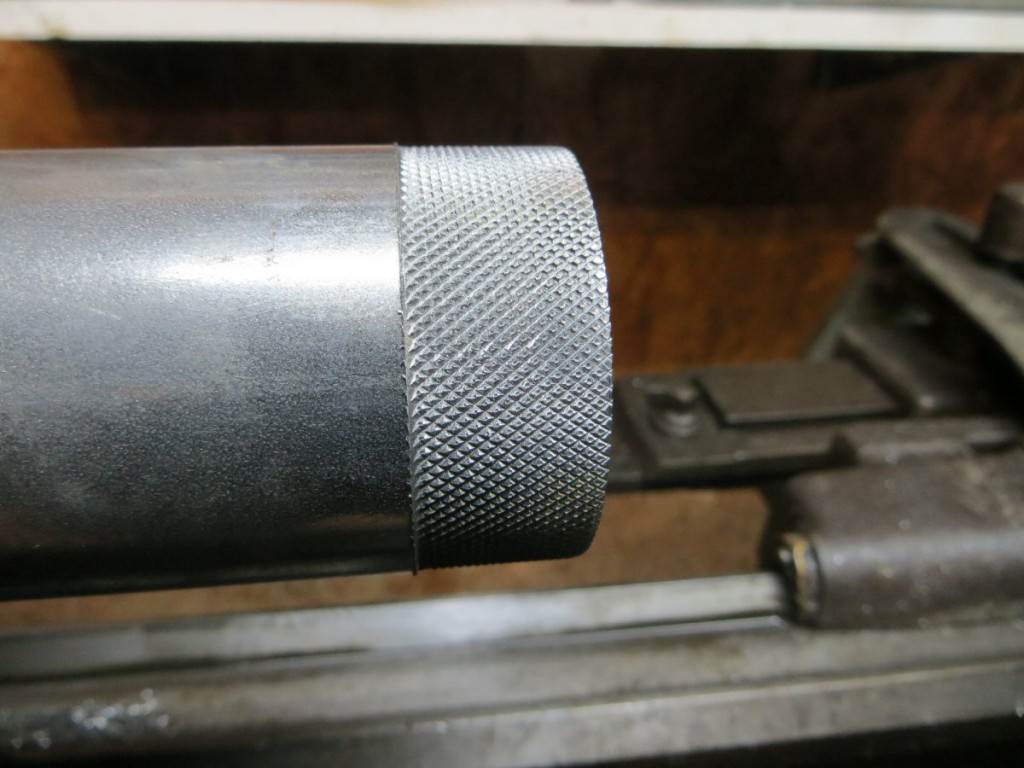

Found a piece of 3/4″ steel bar on the shelf that might work. This is the old knurling tool, which was gracious enough to donate its knurls to the project

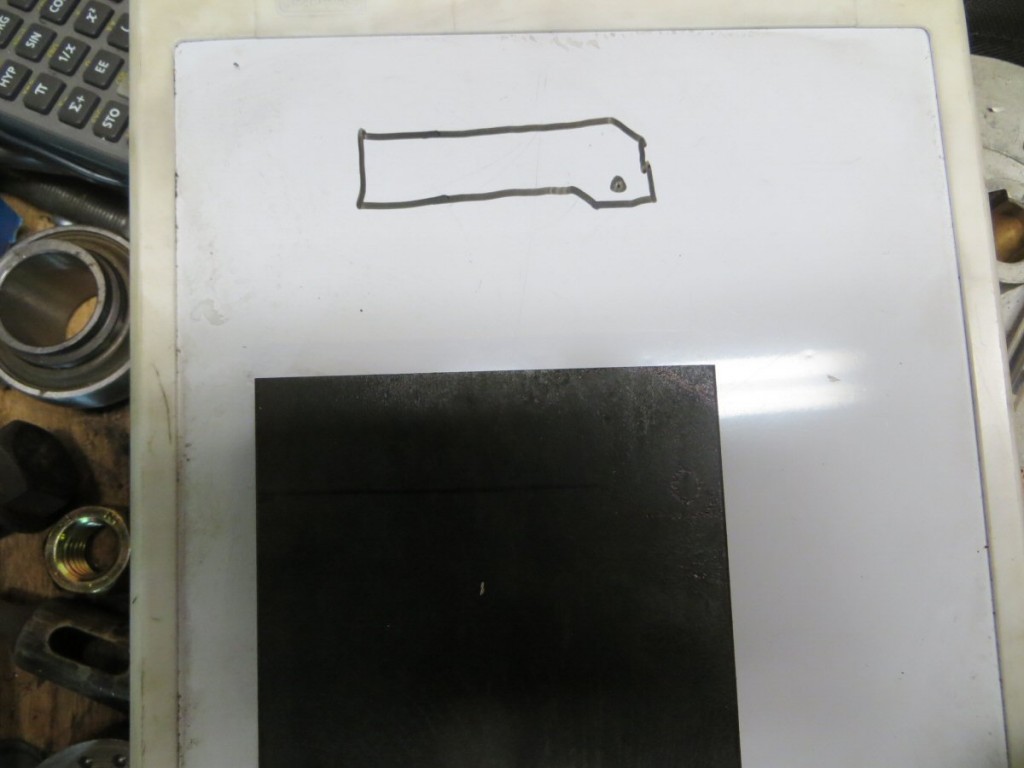

I kind of had an idea of what I wanted it to look like

Off to the band saw to cut out the pieces

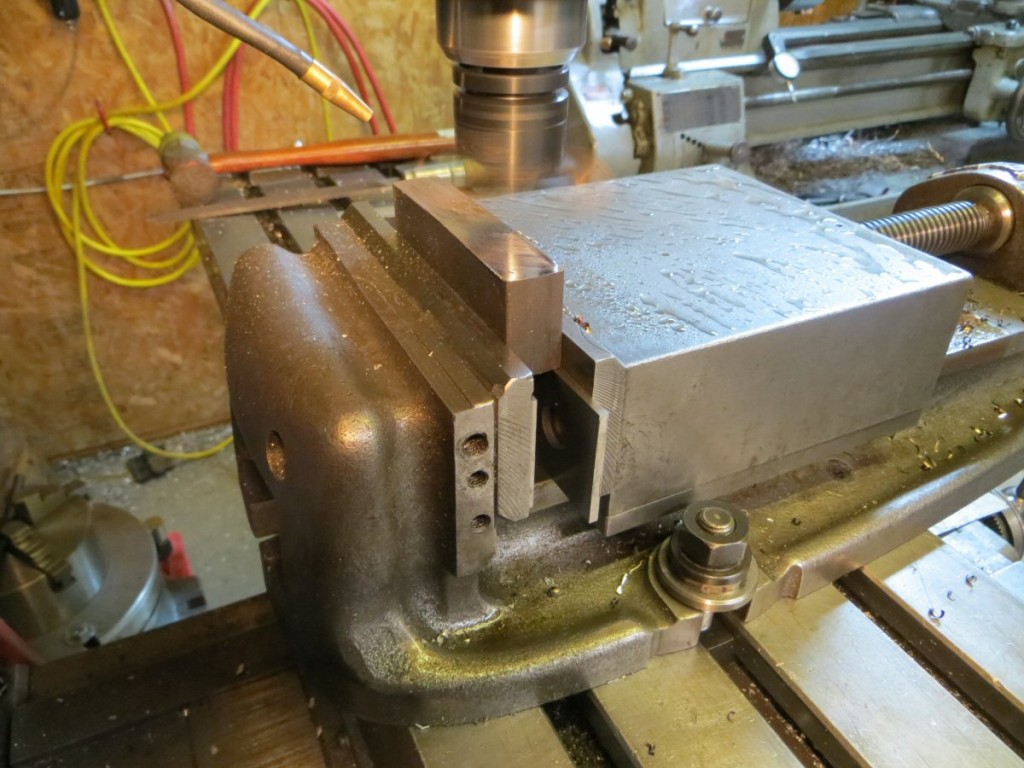

Machining all sides flat and parallel

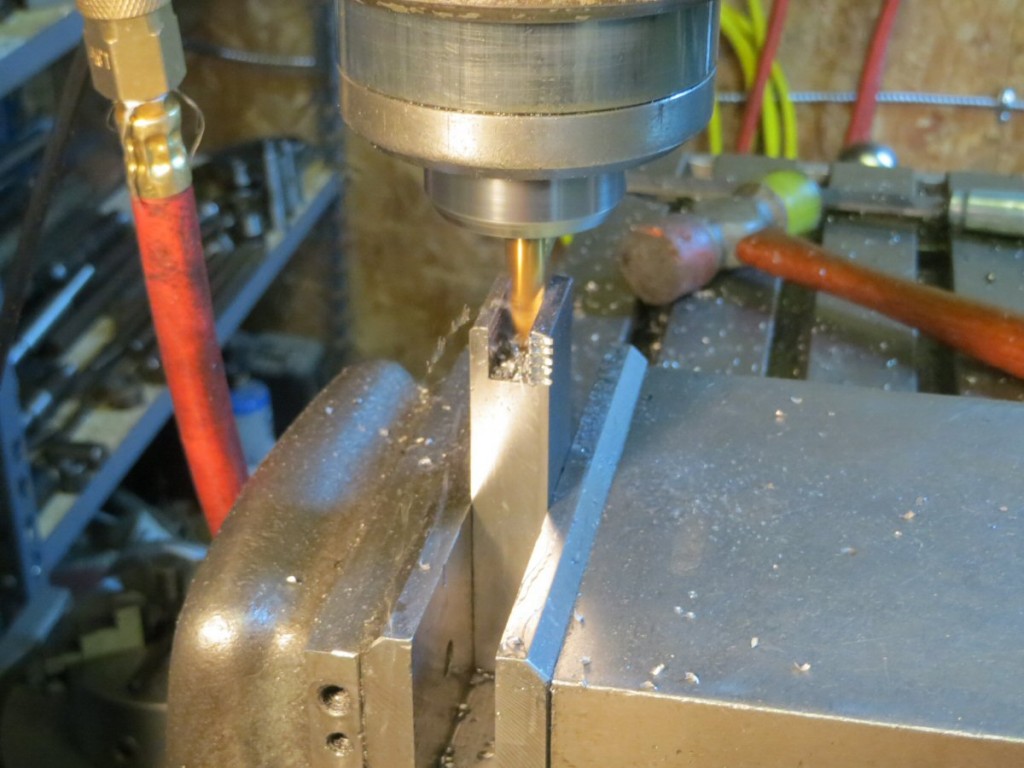

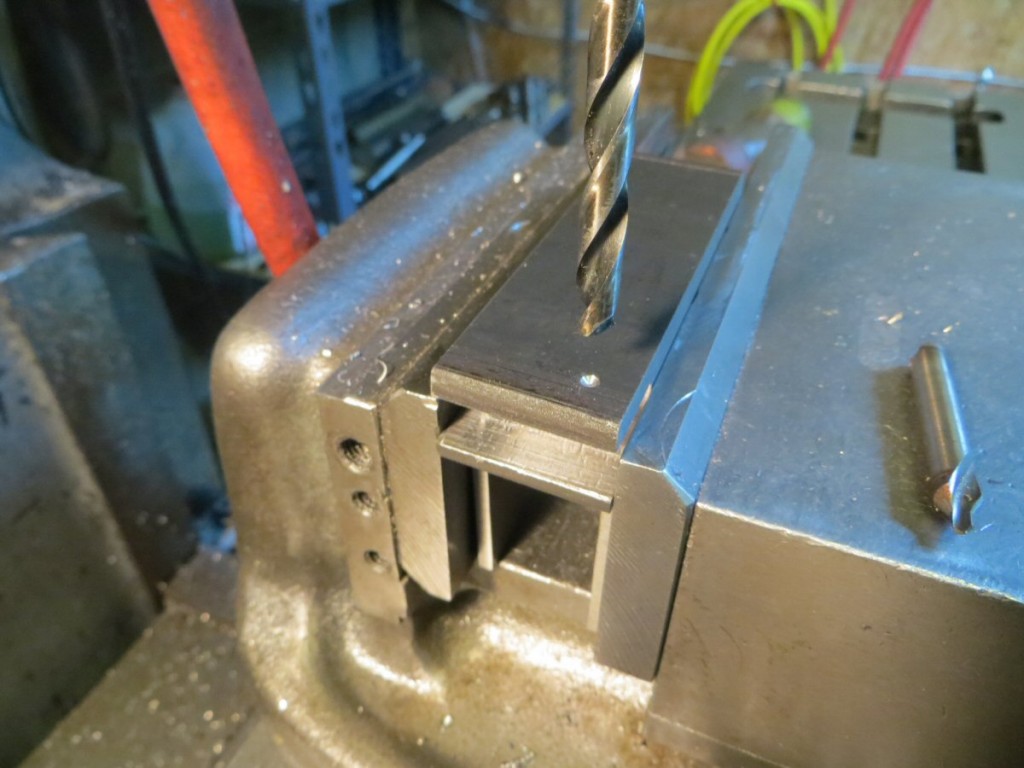

Milling the slots for the knurls

This is the hole for the knurl axle

Pressed in the pins that hold the knurls. Test fit was very good!

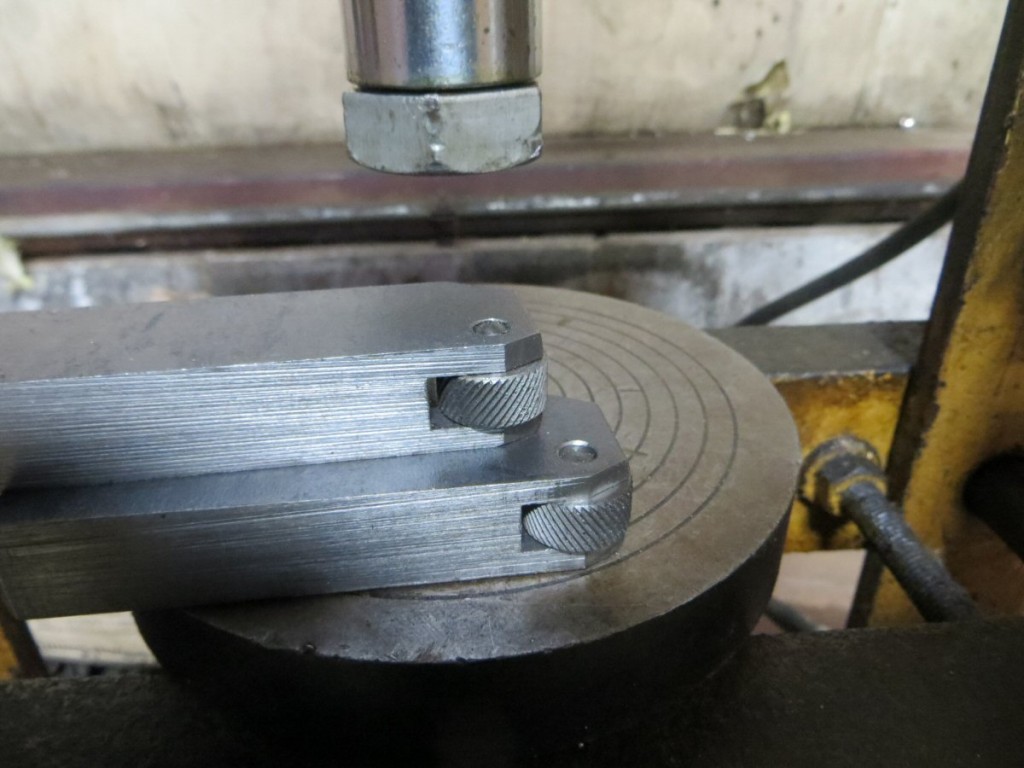

Milling the slots for the clamp, everything pivots so we make a slot instead of a hole

This will serve as the bottom clamp pin and one of the pivot points, it will be cut to 3/4 inch in length to match the thickness of the body

After cutting the pin, we need to face the edges flat in the lathe

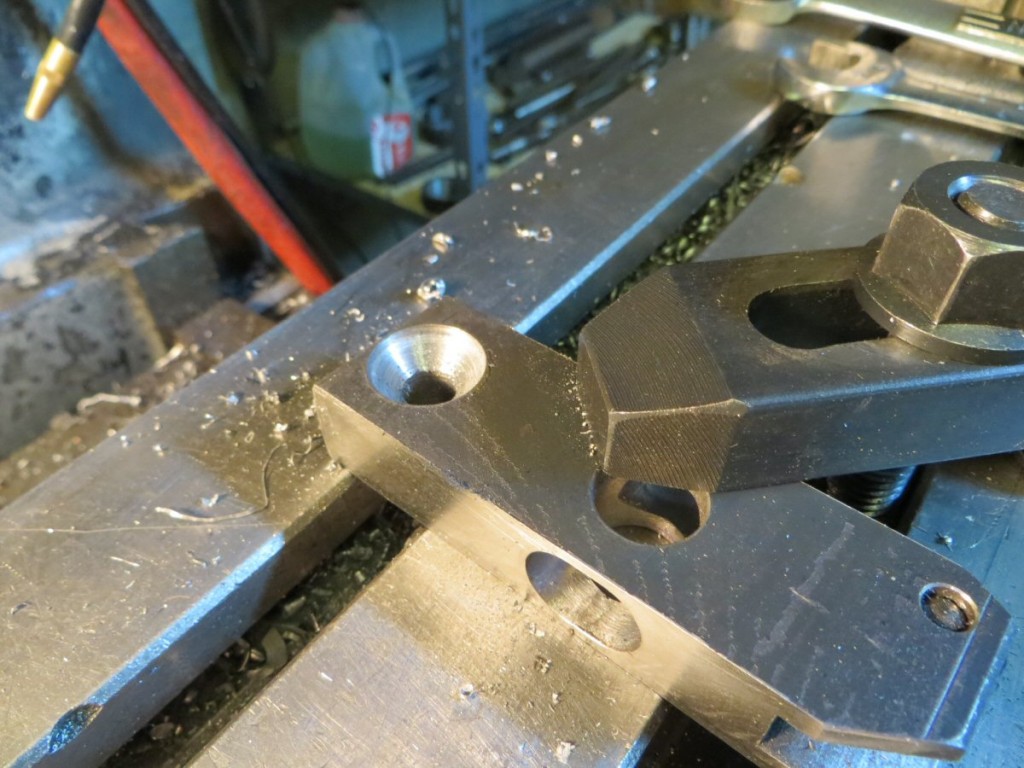

Almost there…the round hole on the sides will hold the pivot pin, the top hole is for the clamp screw. There are two of these, they are identical

Here is the top pin, the bottom pin was threaded to recieve the clamp screw, the top pin has a flat milled to give the clamp screw a good bearing surface

Countersink the mounting holes to use some good looking flat socket head cap screws

The finished piece…I think it looks good! Lets try it out…

Throw in a piece of 2 inch stock and lets see her work…you can see the top of the clamp screw that is used to tighten the knurl during operation. The spring is used to keep the arms apart to make setup easier

It did a great job if I must say so myself…I also made it adjustable for smaller stock…now to get that speed adjust handle for the band saw and knurl it!